229 Products

Filters

Done

-

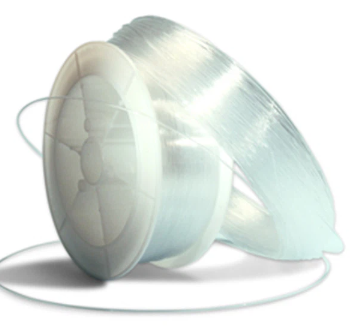

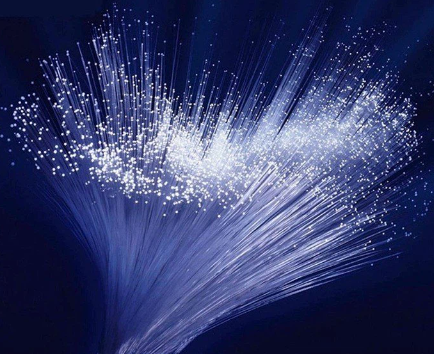

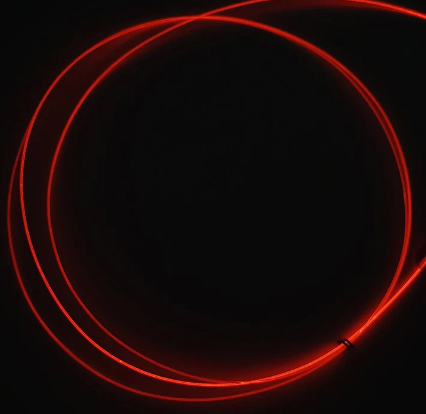

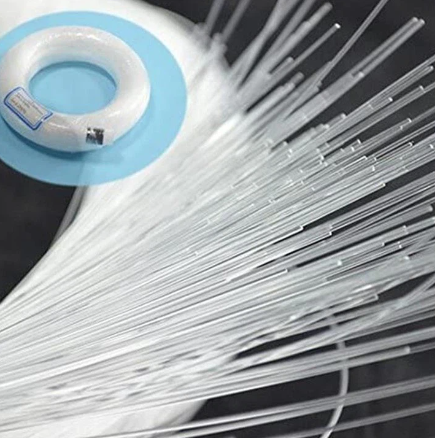

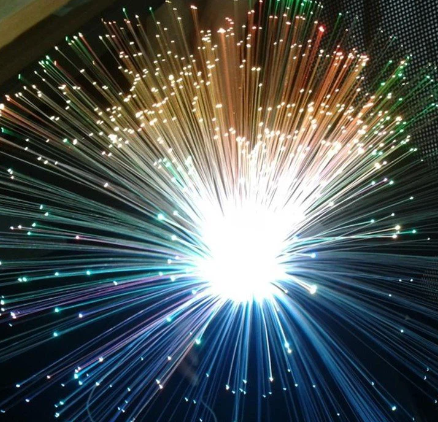

PMMA plastic fiber optic cable, great optical conductivity and flexible to easily create the shape what you need

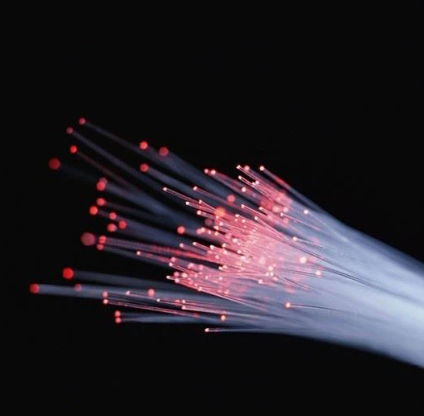

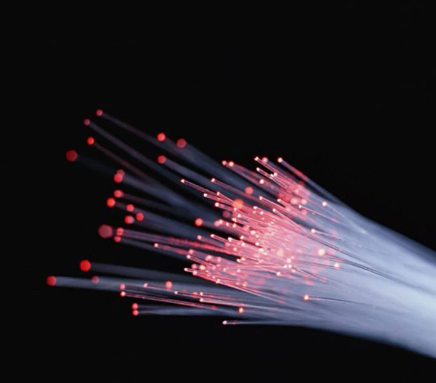

Diameter of each fiber: 0.019in(0.5mm) transparent end glow plastic fiber optic cable

The fiber optic cable is suitable for most light engine diver, widely being made curtain, screen, ceiling sky decoration.