Band saw blades and circular saw blades used for metal cutting machines. These high-performance, quality blades are the result of materials developed in-house, leading edge technologies and thorough manufacturing and quality management.

27 Products

-

Blade suitable for cutting general steel, cast iron and nonferrous metal materials with small diameters.

Blade tooth tips made of AMADA’s original special alloy tool steel

AMADA’s proprietary heat treatment technology to give unparalleled toughness and hardness to carbon blades

Suitable for cutting general steel, cast iron and nonferrous metal materials with small diameters

-

Versatile carbon contour blade available in different sizes.

Versatile contour blade with the longest history and heritageThis is a contour blade made of AMADA’s original material with special heat treatment.

This model has a much wider variety of sizes compared to other manufacturers’ products.

It is suitable for not only metal materials but also lumber and plastic materials. -

Thick blade capable of cutting a curved contour under harsh cutting conditions.

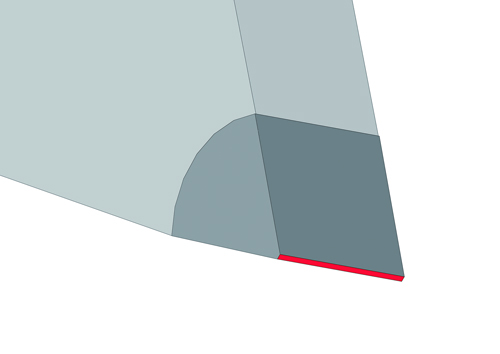

Developed for auto contour curve cutting under harsh cutting conditions

This model is the thicker version of A.

It features AMADA’s unique tooth profile design with a 5˚ positive rake angle in the same fashion as A. Long-lasting excellent sharp cutting is ensured. -

Carbide blades with improved durability intended for general-purpose band saws.

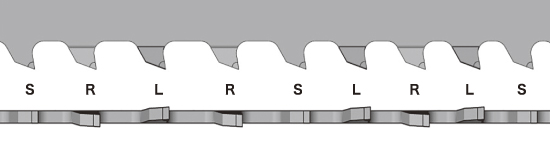

Set tooth type adopted

The adoption of the set tooth type, which has been used for a wide variety of blades and highly reputed, helps reduce cutting resistance and minimize blade deviation.

Tooth tip micro-chamfering

Micro-chamfering minimizes tooth tip chipping of general-purpose band saws during cutting.

-

Blade capable of cutting difficult-to-cut materials at a high cutting rate such as stainless steel and hot work die steel materials.

Five dispersed kerf type tooth shape

High speed cutting and lower cutting resistance during the cutting of difficult-to-cut, large materials (alloy tool steel and stainless steel).Tooth tip micro-chamfering

Delivers high speed cutting and reduces tooth chipping.EXCOAT-DP

Super levels of hardness, high resistance to temperatures, and strengthened coating adhesion technology. -

Blade suitable for cutting difficult-to-cut materials such as Inconel and titanium alloy.

Flat-Set type and Triple-Chip tooth profile (FST tooth geometry)

Dependable sawing on highly abrasive materials.Sharp-edge tooth tip (Sharpest tooth form)

Increased tooth penetration on hardened materials.Utilizing a new and improved grade of carbide chip

Optimized blade material with improved wear resistance.

Increased edge material hardness compared to conventional products.Wide set specification of measure against pinching

Lineup of AXCELA H WS improved measure against pinching for most difficult-to-cut materials. -

Standard model suitable for difficult-to-cut materials.

Cutting surface improved

Excellent in straightness and symmetrical tooth shape/dove tail tooth shape two-piece pattern.Cutting performance improved

Enhanced cutting performance from a tighter tolerance grind.Chipping suppressed

Best suited carbide tip improved chipping resistance. -

Carbide blades with excellent vibration isolation performance.

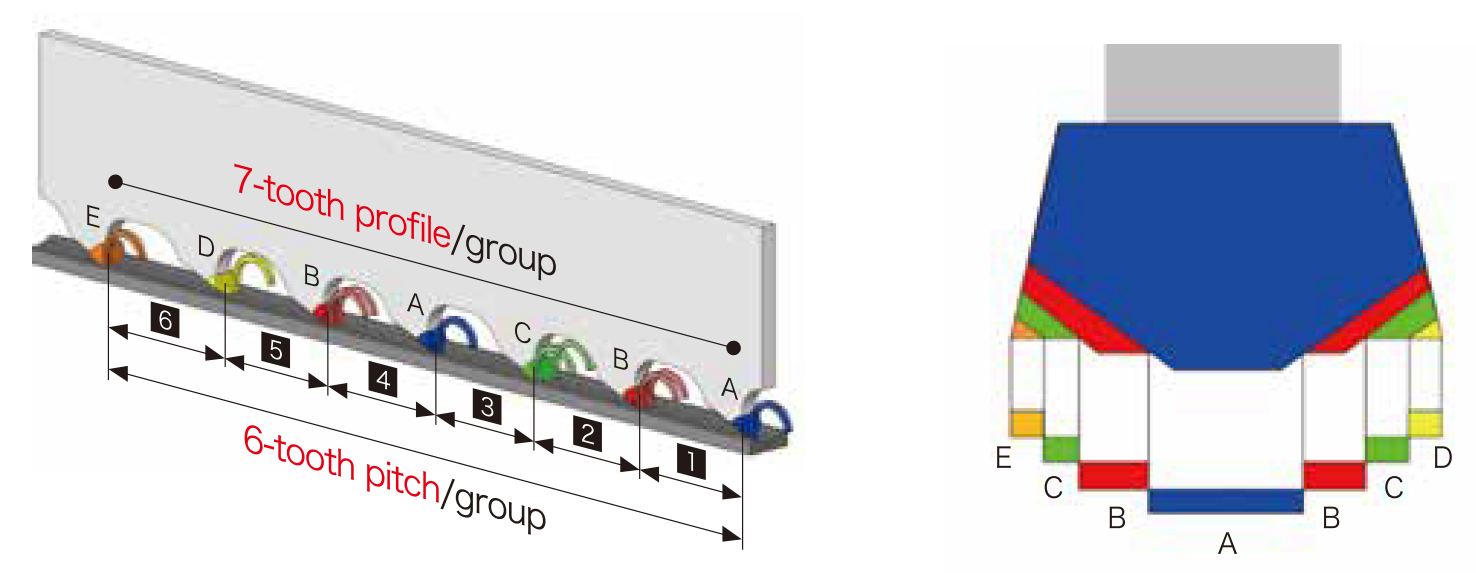

Reduced chattering vibrations by long pattern

The single long pattern featuring 7-tooth per group x 6-tooth pitch = 42-tooth pitch/pattern with a kerf dispersion tooth profile contributes to minimized vibrations with the same frequency and reduced vibrations during cutting.

Tooth tip with sharp edge

The sharp tooth tip form ensures enhanced cutting performance. -

Blade suitable for cutting general steel, cast iron and nonferrous metal materials with small diameters

Blade body with improved fatigue strength.Blade tooth tips made of AMADA’s original special alloy tool steel

AMADA’s proprietary heat treatment technology for improving the fatigue strength of the blade body

Suitable for cutting materials with small diameters, such as general steel, cast iron, nonferrous metal and tool steel materials that may cause a high degree of cutting resistance

-

Blade capable of cutting various materials ranging from roll-formed section steel to solid materials with small diameters.

Blade made of modified high speed steel characterized by significantly improved toughness, based on M42 cobalt high speed steel

Innovative twin set & proprietary tooth profile in the Hi-Lo configuration to prevent overload cutting

Positive rake angle for higher cutting performance

Special treatment and processing to eliminate break-in process

This blade is developed for the purpose of preventing chipping and expanding coverage. It is suitable for cutting roll-formed section steel, structural steel mild steel materials with small diameters

-

Triple hybrid tooth profile

Gulf galette shape improves blade fatigue life.

Chip curler improves chip discharge and suppresses bending.

High positive rake angle reduces cutting resistance when cutting difficult to cut materials.Adoption of AMADA M71 High-Speed Steel

AMADA’s exclusive M71 HSS with a special heat-treatment process greatly improves cutting performances and blade life.EXCOAT-DP

Super levels of hardness, high resistance to temperatures, and strengthened coating adhesion technology. -

Bi-metal contour blade made of high speed steel and designed for cutting difficult-to-cut materials.

Bi-metal blade developed for contour machines

“No breakage, no bend and long-lasting sharp cutting” – three requisites essential to blades for contour cutting of various steel materials

AMADA’s original tungsten high speed steel for the blade teeth and tough special spring steel for the blade body

-

Best suited for medium-to large-sized difficult-to-cut materials, such as stainless steels and hot die steels.

Adoption of AMADA M71 high-speed steel

Wear resistance is markedly improved by a cutting edge of the AMADA M71 featuring 1000 HV or the highest hardness of cast high-speed tool steels.Variable gullet depth for better chip disposal

All tooth tips effectively work to reduce cutting resistance.Highly positive rake angle

Enhanced ability of the saw blade to into hard materials. -

Blade suitable for cutting structural steel materials (blade advantageous in tooth chipping resistance).

The “Protector” located on the tooth tip relief faces prevents excessive cutting and continuous tooth chipping

Innovative blade developed with a focus on the prevention of chipping during the cutting of structural steel materials subjected to severe vibration

Special treatment and processing to eliminate the need of break-in cutting

Blade made of modified high speed steel characterized by significantly improved toughness, based on M42 cobalt high speed steel