Extraordinarily sharp carbide tipped blades adopted as the blade material.

Carbide Tipped Band Saw Blades

6 Products

-

Carbide blades with improved durability intended for general-purpose band saws.

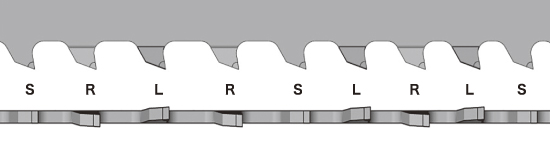

Set tooth type adopted

The adoption of the set tooth type, which has been used for a wide variety of blades and highly reputed, helps reduce cutting resistance and minimize blade deviation.

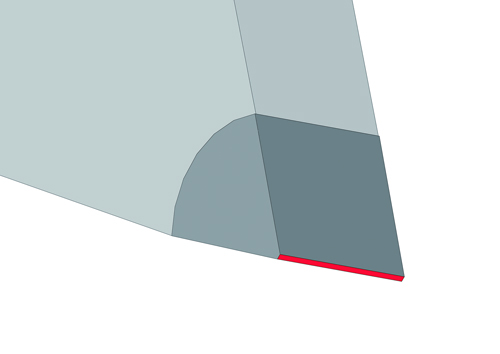

Tooth tip micro-chamfering

Micro-chamfering minimizes tooth tip chipping of general-purpose band saws during cutting.

-

Blade capable of cutting difficult-to-cut materials at a high cutting rate such as stainless steel and hot work die steel materials.

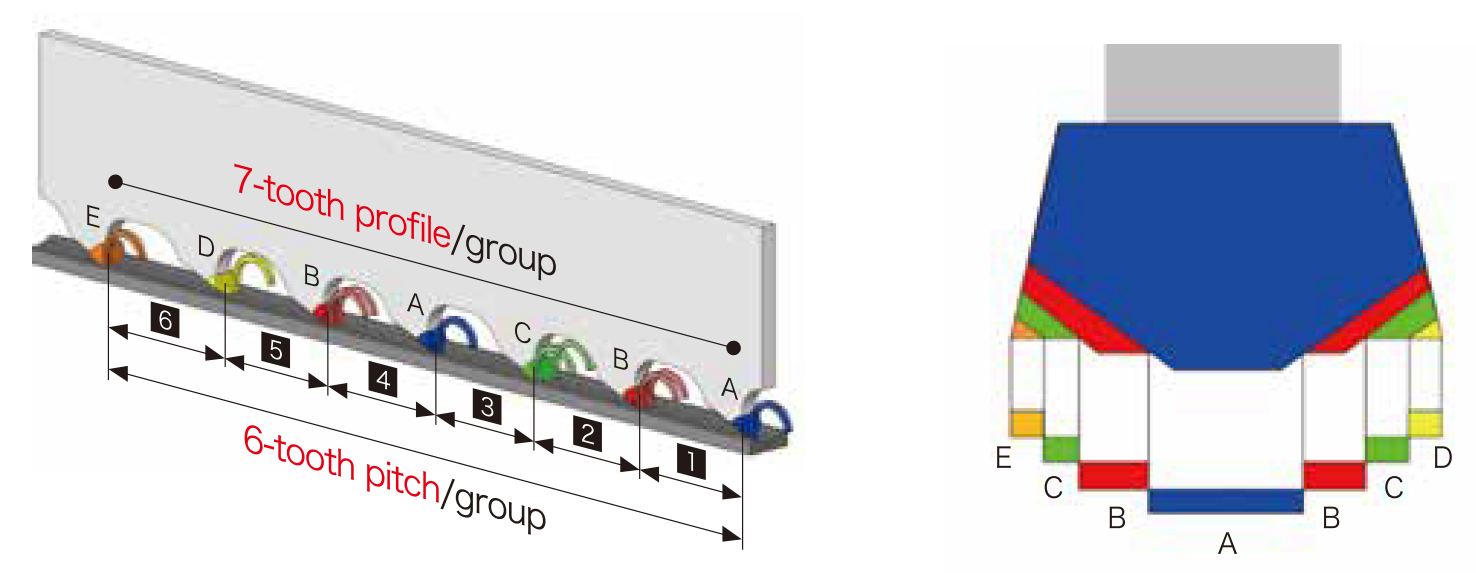

Five dispersed kerf type tooth shape

High speed cutting and lower cutting resistance during the cutting of difficult-to-cut, large materials (alloy tool steel and stainless steel).Tooth tip micro-chamfering

Delivers high speed cutting and reduces tooth chipping.EXCOAT-DP

Super levels of hardness, high resistance to temperatures, and strengthened coating adhesion technology. -

Blade suitable for cutting difficult-to-cut materials such as Inconel and titanium alloy.

Flat-Set type and Triple-Chip tooth profile (FST tooth geometry)

Dependable sawing on highly abrasive materials.Sharp-edge tooth tip (Sharpest tooth form)

Increased tooth penetration on hardened materials.Utilizing a new and improved grade of carbide chip

Optimized blade material with improved wear resistance.

Increased edge material hardness compared to conventional products.Wide set specification of measure against pinching

Lineup of AXCELA H WS improved measure against pinching for most difficult-to-cut materials. -

Standard model suitable for difficult-to-cut materials.

Cutting surface improved

Excellent in straightness and symmetrical tooth shape/dove tail tooth shape two-piece pattern.Cutting performance improved

Enhanced cutting performance from a tighter tolerance grind.Chipping suppressed

Best suited carbide tip improved chipping resistance. -

Carbide blades with excellent vibration isolation performance.

Reduced chattering vibrations by long pattern

The single long pattern featuring 7-tooth per group x 6-tooth pitch = 42-tooth pitch/pattern with a kerf dispersion tooth profile contributes to minimized vibrations with the same frequency and reduced vibrations during cutting.

Tooth tip with sharp edge

The sharp tooth tip form ensures enhanced cutting performance.